Diet for a Beef Animal Fed for Slaughter.

Finishing Beef Cattle On The Farm

By Paul Beck, David Lalman

- Jump To:

- Selection

- General Facility Considerations

- Finishing Options

- Forage Finishing

- Grain Finishing in Confinement

- Grain Finishing On Pasture

- Live Weight to Retail Cuts

- Postmortem Aging Effects on Beef Tenderness

Rural landowners often are interested in raising livestock to slaughter for personal consumption, local marketing or for normal commodity markets. Advantages to raising your own beef include having control over calf quality and choice of how the calf is finished out. Calves can be finished on grass, grain and grass, or high concentrate diets. There are disadvantages to consider when fattening your own beef. Disadvantages may include the need to purchase a calf, extra labor for feeding, sufficient land set aside for forage-finishing, purchasing and storage of expensive feedstuffs for grain-finishing, or purchasing freezers to store the beef after slaughter. Calves also can get sick and may require veterinary attention, and owners must realize the longer the ownership, the more risk of death losses due to injury or illness. This fact sheet covers facility and calf selection, feeding options and slaughter considerations for finishing calves on the farm. For more in-depth information on nutrition, health and growth promoting compounds see AFS-3302 An Introduction to Finishing Beef.

Selection

Calves selected for farm-raised beef vary in type. Budget, marketing niches and end product goals will determine the type of calf that works best. Small-framed dairy calves, like Jersey calves, can have exceptional meat quality; however, percent retail product and size of cuts, like ribeye steaks, will be fairly small. A Large-framed, heavy-muscled beef breed will have very good cutability (high percentage retail product) but calves of this type can take longer to reach maturity, will likely be slaughtered prematurely and freezer space may be inadequate to store all the cuts. Calves of beef breeds that are moderate-framed and early maturing with good muscling are ideal for most farm raised beef programs. Producers that desire greater lean may desire calves of traditional Continental breeds like Charolais and Limousin; whereas, producers that desire the flavor and juiciness of steaks with more marbling (intramuscular fat that determines USDA Quality Grade) may prefer calves of predominately English breeding such as Hereford, Red Angus, Black Angus or Shorthorn. Finishing calves with more than 25% Brahman influence can tend to reduce cutability and tenderness.

Bulls should be castrated early in life, preferably at birth or by three months of age. Steaks from intact bulls can be leaner and tougher than steaks from steers. Aggressive activity of group-fed bulls can become a handling issue as well as increased chances for animal injury and bruising. Heifers make good farm-raised beef candidates. Heifers often are kept for breeding, and at the end of the breeding season, any heifer that did not become pregnant can be easily finished for slaughter. Because they are earlier-maturing, heifers generally fatten quicker at a lighter bodyweight and have a slightly poorer feed conversion ratio than males.

General Facility Considerations

Shade and wind breaks. Finishing (forage- or grainfinishing) and marketing goals (personal use or sale) will determine the land and facilities needed. Whether finishing calves on pasture or in dry lot confinement, calves will be more comfortable if they have access to shade during summer and a wind break during winter. Calves may grow adequately without shade or a wind break during part of the year, but shelter from the elements is necessary when conditions exceed the animal's thermo-neutral zone. The necessity for access to shade and wind break may be a personal preference to the level of animal comfort desired and marketing or may be a necessity depending on the environment. If the goal is to market beef locally, buyers may be interested in farm tours to see where the beef was produced. Buyers of locally grown beef are making their buying decision based in part on their perception of how calves should be reared and if calves don't have access to summer shade or winter shelter, someone will eventually make it a point to ask.

Handling facilities. Cattle handling facilities at a minimum should include a catch pen with a lane and headgate to be able to vaccinate, treat illness, castrate and dehorn. Poorly maintained working facilities can be a source of injury and bruising that may cause product loss. Walk through working facilities and look for possible points of injury, such as protruding bars, bolts or nails.

Feed storage and handling. Wasted feed due to poor storage and handling techniques increases the cost of producing beef. Feeds should be stored in a dry location to reduce the chances of molding. Feed storage facilities need to be kept clean to keep pests (rodents and insects) at a minimum. It is essential feeding rates be managed to limit build up of uneaten feed. Feed troughs also should be kept clean to minimize leftover feed spoilage and buildup of uneaten portions due to mixing fresh feed with spoiled feed in troughs.

Hay used in forage-finished beef programs should be high in quality. Storing hay under UV-protective tarps or in barns will reduce storage waste. Feeding round bales in protected rings that either keep the bale centered or have a metal sheet around the bottom minimize feeding waste (see the fact sheets BAE-1716 Round Bale Hay Storage for more in depth information on hay storage losses and PSS-2570 Reducing Winter Feed Costs for more information on improved hay utilization)

Finishing Options

Forage- versus Grain-finishing. The objective here isn't to start a grass- or grain-finished debate; there is room for both in a local farm-raised beef market. It is important to understand common characteristics of forage- versus grain-finished beef when deciding which option is best for beef produced on-farm for personal use or marketing. In general, the typical beef consumer of the U.S. prefers the flavor of grain-fed beef. By comparison, ground beef from cattle finished on forage has been characterized as having a 'grassy' flavor. Grass-fed ground beef also can have a cooking odor that differs from grain-fed beef. The visual appearance of the fat of grass-fed beef can be more yellow in color due to carotenoids in comparison to grain-fed beef fat, which appears white.

An overview of 23 published studies from 1978 to 2013 showed that cattle finished on pasture gained 1 pound less per day than cattle fed high-concentrate diets in confinement (1.55 vs 2.54 pounds per day.) Forage-finished cattle were finished at a lighter weight (~950 lb pounds) than grain-finished cattle (~1,100 pounds) and dressed at a lower percentage (56% vs 60%). Forage-finished cattle had 0.2 inches of back fat vs 0.5 inches for feedlot finished and as a result are leaner when delivered for slaughter compared to grain-finished cattle. Leaner beef is generally scored by taste panelists as being less tender and less juicy compared to fatter beef. So, the health-conscientious consumer seeking forage-raised beef is usually willing to accept trade-offs of flavor, tenderness and juiciness for a leaner beef that may contain a greater proportion of heart-healthy fats. Whereas, other consumers may continue to seek the grain-finished beef characteristics, but want to support local sources of grain-fed beef.

Forage Finishing

Forage finishing capitalizes on the beef animal's ability to convert forage into muscle protein through the aid of microbial breakdown of forage celluloses in the rumen. Since cattle are naturally grazing animals, some consumers seek out beef from cattle reared in their "natural environment". The first challenge to forage-finishing is having a sufficient area of grazeable land. Forage dry matter intake is thought to be maximized when forage allowance is kept above 1,000 pounds per acre. Forage-based systems may require 1 acre or up to 10 acres per calf depending on fertilization, weed control, seasonal forage productivity, forage species and management. Even with good forage management, hay is often needed for two months to four months during winter. To sustain good calf growth rates and reduce the number of days required to finish calves on a forage-based system, high-quality hay should be offered when pasture grasses are limiting. Supplementation with concentrate feeds such as soybean hulls may be needed to boost gains and allow for fat deposition when hay or pasture is moderate to low quality. Soybean hulls are recognized by the American Association of Feed Control Officials as a roughage source and is approved for grass-fed beef claims by the USDA. Other organizations set differing standards for definition of 'grass-fed' these organizations offer marketing alliances and certification, if you are (or want to be) a member, you can refer to their guidelines for animal care and approved management and nutrition.

The second limitation to forage-finishing is calf growth response. As forage quality, forage quantity and environmental temperatures fluctuate throughout the year, average daily gain may range from seasonal highs of greater than 2.0 pounds per day to seasonal lows of 0.5 pound per day or less. As a result, calves grown in forage-finishing systems often are slaughtered before they reach the same degree of fatness of grain-finished cattle. Forage-finished calves often will be slaughtered near 1,000 pounds live weight. It will take over a year (367 days) to grow a 500-pound calf to 1,000 pounds if its average daily weight gain is 1.5 pounds per day. Some extensive forage-finishing systems may require a longer duration for calves to reach slaughter weight if forage quality and quantity restrict growth to no more than 1 pound per day.

Intensive spring and summer forage-finishing systems can be accomplished with mixtures of forages like legumes, perennial grasses, annual grasses and brassicas. Research at Clemson University compared forage species for finishing calves on pasture during late-spring and summer months. Calves used in the study were grown the previous winter on rye/ryegrass and fescue. Finishing forages studied included alfalfa, bermudagrass, chicory, cowpea, or pearl millet. Pastures in this study were stocked at 1.7 acres per calf with the exception of pearl millet which was stocked at 0.8 acres per calf. The amount of pasture forage maintained during the study ranged from 1,300 pounds to 2,500 pounds per acre. Table 1 is a summary of the study results.

Steers grazing bermudagrass pastures gained 1.7 pounds per day, while steers grazing alfalfa (2.8 pounds per ), chicory (2.5 pounds per day) and cowpea (1.9 pounds per ) gained more rapidly and had greater backfat thickness at slaughter. Steers grazing pearl millet only gained 1.2 pounds per day and had the least backfat at slaughter. Among the finishing systems, fatty acid composition tended to be similar and the ratio of the polyunsaturated fats to saturated fats was similar. In this study, all treatments had shear force values that would be considered at or below the threshold for consumer accepted tenderness.

Research in Georgia (Table 2) compared forage-finishing on toxic fescue and non-toxic, endophyte-infected tall fescue starting in the fall and ending in the spring for a 176-day grazing period. The stocking rate of the toxic fescue was 1.5 steers per acre and the stocking rate of the non-toxic fescue was one steer per acre. When fescue became limited during winter months (January and February), calves were grouped into a single pasture and were fed bermudagrass hay. In general, toxic fescue reduced growth rate which resulted in lighter carcass weights, but tenderness and consumer panel attributes were not enhanced by non-toxic fescue. WarnerBratzler shear force for the steaks from is trial were much higher than the threshold level of acceptable tenderness (10 pounds) and would be considered tough by industry standards. When carcasses were aged for 14 days, shear force values decreased to 10 pounds, a level that would be on the upper limit of threshold WBSF values considered acceptable for tenderness by consumers (Realini et al., 2005).

Table 1. Growth and carcass attributes of calves finished on different forages during late-spring and summer (adapted from Schmidt et al., 2013).

| Alfalfa | Bermudagrass | Chicory | Cowpea | Pearl Millet | |

|---|---|---|---|---|---|

| Grazing days per acre | 68 | 89 | 55 | 46 | 112 |

| Start weight, lbs | 893 | 1,047 | 931 | 1,058 | 1,052 |

| End weight, lbs | 1,184 | 1,274 | 1,137 | 1,221 | 1,155 |

| Average daily gain, lb/day | 2.8 | 1.7 | 2.5 | 1.9 | 1.2 |

| Carcass weight, lbs | 711 | 719 | 675 | 752 | 664 |

| Backfat thickness, inches | 0.30 | 0.2 | 0.30 | 0.27 | 0.18 |

| Dressing, % | 60.0 | 56.4 | 59.4 | 61.6 | 57.5 |

| Quality grade | 3.5 | 3.8 | 3.2 | 4.4 | 3.8 |

| Warner-Bratzler shear force, lbs | 8.8 | 10.6 | 9.9 | 8.8 | 9.9 |

| Consumer preference, % | 40% | 5% | 10% | 20% | 25% |

Quality grade code: 3 = Low Select, 4 = High Select, 5 = Low Choice (higher is associated with greater fat and less lean) Warner-Bratzler shear force (lower is associated with greater tenderness, all treatments were at or below the threshold of 10 generally recognized as tender by consumers)

Table 2. Growth and carcass attributes of calves finished on toxic and non-toxic, endophyte-infected fescue from autumn through spring (adapted from Realini et al., 2005).

| Toxic Fescue | Non-toxic Fescue | |

|---|---|---|

| End weight, lbs | 906 | 992 |

| Carcass weight, lbs | 491 | 541 |

| Backfat thickness, inches | 0.17 | 0.21 |

| Dressing, % | 54.2 | 54.5 |

| Quality grade | 3.0 | 2.8 |

| Warner-Bratzler shear force, lbs | 13.2 | 15.4 |

| Consumer panel – Chewiness score | 2.8 | 3.7 |

| Consumer panel – Juiciness score | 2.7 | 2.4 |

Quality grade code: 3 = Low Select, 4 = High Select, 5 = Low Choice (higher is associated with greater fat and less lean) Chewiness score: 1-to-5 scale with 1 being most desirable and 5 being least desirable. Juiciness score: 1-to-5 scale with 1 being least desirable and 5 being most desirable.

A study at the University of Missouri examined the effect of adding either red clover or alfalfa to a fescue based foragefinishing system for a three-month finishing period from late March through July. The amount of legume in these systems was 38% in the alfalfa system and 16% in the red clover system. Final weight of calves did not differ between the fescue and combined legume response and averaged 1,035 pounds. Calves in the alfalfa system were 50 pounds heavier at the end of the study compared to the red clover system, which could had been influenced by difference in legume forage availability. The fatty acid composition of fat taken from the loin muscle did not differ among forage types.

Another study at Clemson (Table 3) compared a legume system to a grass system with or without supplemental corn fed at 0.75% body weight. The legume systems utilized alfalfa and soybeans while the grass system utilized non-toxic fescue and sorghum-sudangrass. While corn supplementation provided some beneficial responses, these responses were independent of forage system; therefore, the difference in forage system is summarized in Table 3. Forage type had little influence on fatty acid composition; however, greater fat soluble vitamin content was detected in the loin muscle of grass finished beef in this study.

As a general summary, the forage system chosen will first be dictated by forage species that are already present. Replacing forages with alternative species or interseeding with complementary forages will be dictated by soil type, topography, and soil fertility. Calves can be forage-finished on grasses, legumes or combination thereof. Current research results do not suggest any single system is ideal based on carcass quality and consumer sensory comparisons.

Grain Finishing in Confinement

While ruminants have the distinct ability to convert cellulose into muscle protein through ruminal microbial fermentation, there remains a history of fattening cattle on feedstuffs other than forage long before the establishment of the modern confinement feedlot industry. Early fattening in America included root crops, "Indian corn", tree fruits and brewing and distillery mash. Confinement feeding in early America also was a mechanism to concentrate manure for fertilizer. Unlike forage-finishing, grain-finishing requires less land. Depending on soil type and topography, as little as 150 square feet per calf of pen space with a feed and water trough is sufficient. Sometimes, locally grown beef producers may allow a much larger area to keep grass cover in the lot instead of allowing the pen to become a dirt lot.

Table 3. Growth and carcass attributes of calves finished for 98 to 105 days in a grass system or a legume system (adapted from Wright et al., 2015).

| Grass System | Legume System | |

|---|---|---|

| End weight, lbs | 1,142 | 1,166 |

| Carcass weight, lbs | 669 | 697 |

| Backfat thickness, inches | 0.33 | 0.37 |

| Quality grade | 4.5 | 4.7 |

| Consumer panel – Tenderness score | 2.8 | 2.8 |

| Consumer panel – Juiciness score | 2.0 | 1.9 |

Quality grade code: 3 = Low Select, 4 = High Select, 5 = Low Choice (higher is associated with greater fat and less lean) Consumer panel scores converted to 1-to-5 scale with 1 being least desirable and 5 being most desirable.

When finishing calves in groups, 22 inches to 26 inches of linear trough space per calf is needed when all calves will be eating at once on the same side of the trough. Grain diets are much drier than pasture diets and when calves are fed in confinement, they are usually watered from a trough. Keeping the water trough clean is extremely important. A depression in water intake can cause a reduction in feed intake and slow growth rate. During hot weather, a calf near finishing weighing 1,000 pounds or more can consume more than 20 gallons per day (for more on water requirements of finishing calves see AFS-3302 An Introduction to Finishing Beef.)

Many associate grain-fed beef with corn-fed beef. From 2005 through 2011, corn use for ethanol grew to the point the total use for ethanol reached that of feed and residual use. A feedlot finishing diet today may contain 6% to 12% roughage, up to 50% byproduct feeds such as distiller's grains and corn gluten feed and cereal grains (mostly corn) representing 50% or more of the finishing diet.

Mimicking feedlot diets may not be practical when finishing calves on-farm; however, similar steps used in the commercial feeding industry should be adopted including:

- Calves should be transitioned from a roughage diet to the final high concentrate diet over a three-week period. This is called a step-up program.

- Feed calves at least twice per day when the final diet does not contain built in roughage or is not formulated to be self-fed or self-limiting.

- Include 10% to 15% roughage in the final diet for increased rumen health and reduced acidosis.

- Feed calves a balanced diet (protein, minerals, mineral ratios and vitamins).

- Adjust feed amount as calves grow.

Consult with a nutritionist to develop a ration based on locally available ingredients or use a commercial finishing ration. Some feed mills offer "bull development rations" that can also be used as a decent finishing ration. These "bull development rations" sometimes include enough cottonseed hulls and byproduct feeds that additional roughage is not needed.

In addition to distiller's grains and corn gluten feed, other byproducts such as soybean hulls may be used in finishing diets. Soybean hulls has an estimated feed value of 74% to 80% of corn; whereas, dried distiller's grains has demonstrated a 124% feed value of corn. There is little indication that feeding byproduct feeds changes the marbling of cattle as long as energy density requirements are met for fat deposition. Research results indicate less intensively processed grains (ie feeding whole corn or rolled corn) may result in higher marbling than intense processing methods commonly used in commercial finishing operations (ie high moisture corn or steam flaking). This is thought to be due to the site of starch digestion being shifted to the small intestine with less intensive grain processing supplying more glucose to drive marbling.

Feeding Concentrate and Roughage Separately. Feed milling, mixing and delivery take up much of the daily activities in commercial scale feedyards. This is an equipment-intensive operation with large capital outlays necessary for the feed mill and equipment for feed delivery. On a smaller scale, large investments in feeding systems may not be warranted. Delivery of total mixed diets balanced to meet nutritional needs of finishing cattle adds efficiency to large commercial operations that cannot be matched by smaller-scale finishing operations. Diets formulated for on-farm finishing also can be based on limit feeding the concentrate portion in the trough while allowing calves to have free choice access to pasture or hay for roughage. Research (Atwood et al., 2001) comparing intake and performance by fattening calves offered either a 65% concentrate (rolled barley and rolled corn) total mixed ration with alfalfa hay and corn silage providing the roughage or providing all dietary ingredients offered free-choice for self-selection found that no two animals offered free-choice consumed similar diets or selected diets similar to the TMR. The authors concluded free-choice diet selection was adequate for each individual animal to 'meet its needs'. Performance of cattle fed TMR or offered free-choice selection of diets and feed efficiency were similar between feeding systems.

More recent research from Canada (Moya et al., 2011 and 2014) was conducted to compare performance, efficiency and rumen pH of cattle finished on a TMR based on barley grain (85%), corn silage (10%) and protein/mineral supplement (5%) vs offered concentrate and roughage separately for free-choice selection. All cattle were adapted to the TMR diet and the free-choice diets were available over the 52-day experiment. During the 52 days, cattle selected diets with increasing barley, reaching 70% to 80% of their self-selected diet, but even with the increasing barley in the diet, ruminal pH was similar to calves fed the TMR in the first experiment (Moya et al., 2011). In the first two-week period calves consumed approximately 75% barley grain, increasing to 80% in weeks three and four, and to 85% in weeks five through seven; the average selected diet for cattle offered barley and corn silage was 80% barley grain and 20% corn silage. While in the second experiment, calves offered free- choice access to corn silage and barley grain self-selected diets that were 86% barley and 14% corn silage without altering ruminal fermentation characteristics and blood profiles (Moya et al., 2014). As with previous experiments, cattle given free-choice access to self-select diet ingredients in both experiments performed similarly to cattle fed TMR. These research concluded cattle can effectively self-select diets without increasing the risk of acidosis and maintain production levels for growth and feed efficiency.

If a producer wants to utilize a free-choice, self-selection feeding system where roughage and concentrate are fed separately, a few management steps should be taken.

- A step-up period of increasing grain availability is a must, cattle should be acclimated to the high concentrate diets during at least 20 days;

- Utilize palatable, high-quality hay, silage or roughage source;

- Limit-feed concentrate and practice good feed bunk management;

- If limit-feeding hay – feed hay first, then provide the concentrate portion of the diet;

- Concentrate blends of grains and byproduct feeds are safer than providing grain only;

- Think about safer concentrate feeding alternatives—feeding whole corn is safer than finely ground corn and can be an option for growing and finishing calves

Grain Finishing On Pasture

Hybrid systems have been studied as an alternative to high-concentrate total mixed rations fed in confinement. These systems utilize the roughage supplied by pasture along with additional energy from supplemental concentrates. They may not meet the requirements to meet 'grass-fed beef' claims by the USDA, but do provide free-choice access to pasture.

Self-fed supplements on pasture can be another approach to finishing cattle. Research at Iowa State University (Table 4) examined self-fed dried distillers' grains with solubles mixed 1:1 with either soybean hulls or ground corn. In addition, a mineral that helped balance the calcium-to-phosphorus ratio and contained monensin to improve rate of gain was added at 4% of the mix. The calves were stocked at approximately 2.25 calves per acre of predominately tall fescue pasture. Estimated contributions of self-fed concentrate and pasture to the total dry matter feed intake in this study was 80% and 20%, respectively. The study did not report any issues with digestive upset with self-feeding.

Two studies were conducted at the University of Arkansas (Apple and Beck, unpublished data). In the first trial, calves from spring or fall calving herds were either sent to a Texas Panhandle feedyard for finishing as yearlings following a stocker program or kept at the home operation and supplemented with 1% of bodyweight per head per day with a grain/grain byproduct supplement until slaughter. Steers finished conventionally in confinement gained 4.4 pounds per day, while steers fed concentrate supplement on pasture gained 2.5 pounds per day. Although the finishing period on pasture was 30 days longer on the average, steers finished in the conventional feedlot were 128 pounds heavier at slaughter and dressing percentage was higher 62.5% vs 60.6% for Conventional and pasture, respectively). Conventionally finished cattle were 86% Choice while pasture finished were 78% Select quality grade.

Table 4. Growth and carcass attributes of calves finished on self-fed concentrates (adapted from Kiesling, D.D. 2013).

| Distillers' grains plus solubles:corn [50:50] | Distillers' grains plus solubles:soybean hulls [50:50] | |

|---|---|---|

| Average daily gain, lbs | 3.4 | 3.3 |

| End weight, lbs | 1,302 | 1,291 |

| Carcass weight, lbs | 816 | 807 |

| Dressing, % | 62.6 | 62.5 |

| Backfat thickness, inches | 0.53 | 0.55 |

| Quality Grade | 5.0 | 5.0 |

Estimated concentrate intake was 80% and pasture intake 20%. Quality grade code: 3 = Low Select, 4 = High Select, 5 = Low Choice

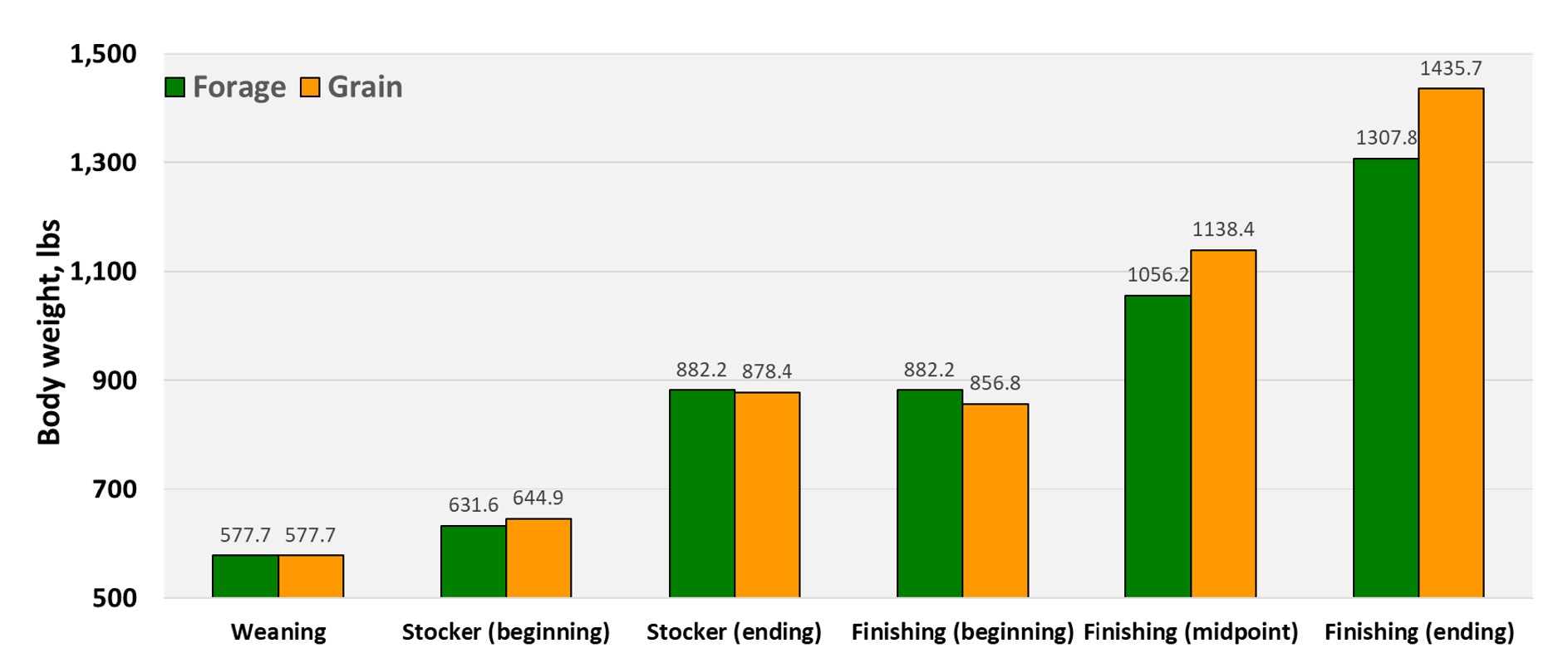

Figure 1. Effect of finishing on pasture (Forage) with 1% of bodyweight concentrate supplement daily or conventional finishing (Grain) on bodyweight of steers.

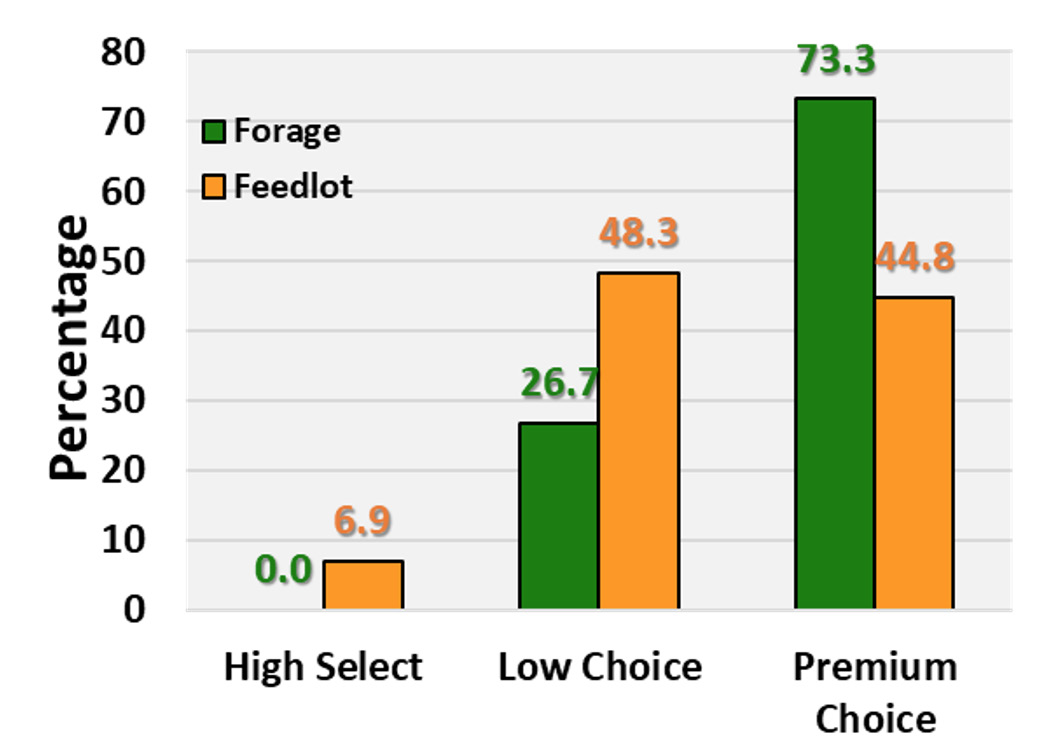

In the next trial, 60 calves were either finished in conventional Texas Panhandle feedyard or were kept on pasture with a grain/grain byproduct concentrate supplement fed at 1.5% of bodyweight daily. Steers finished on pasture with supplement gained 3.6 pounds per day (vs 4 pounds per day for conventional) and were fed 40 days longer than conventional steers, but were still 40 pounds lighter at slaughter. But, hot carcass weights (836 for pasture vs 854 for conventional) were not as impacted as in the previous study, fat thickness was similar for the two treatments (0.62 inches for pasture vs 0.52 inches for conventionally finished) and dressing percentage was likewise similar (63% for pasture and 62.5% for conventional). In this experiment, the cattle finished on pasture with supplement were 100% Choice, with 73% being Premium Choice; while the Conventional steers were 93% Choice, with 45% being Premium Choice. This research indicates acceptable carcass performance can be obtained with limited energy supplementation on pasture.

Figure 2. Effect of finishing on pasture (Forage) with 1.5% of bodyweight concentrate supplement daily or conventional finishing (Grain) on carcass quality grade.

Live Weight to Retail Cuts

The final amount of retail cuts produced from a live calf will be affected by frame, muscle, bone, fat cover and gut capacity/fill. The first measure of yield is dressing percentage which is the percentage of carcass weight relative to live weight. Dressing percentage can range from 58% to 66%. A 1,300-pound steer that yields a carcass weighing 806 pounds would have a 62% dressing percentage. A second measure of yield is retail product. The USDA Yield Grade is a numerical score that is indicative of retail product. A calculated Yield Grade is determined from hot carcass weight, fat thickness at the 12th rib, ribeye area and the combined percentage of kidney, pelvic and heart fat. Percentage of retail products can be calculated from these same measurements. Percent retail product may range from 45% to 55%. A 1,300-pound steer at Yield Grade 3 would have a retail product percentage of 50% which would yield about 650 pounds of retail product. If two individuals purchase a side of beef each, they each can expect 325 pounds of retail product. The yield of retail product will consist of approximately 62% roasts and steaks and 38% ground beef and stew meats. So, a single side of beef that yields 325 pounds of retail product also would yield approximately 201 pounds of roasts and steaks and 124 pounds of ground beef and stew meat.

Postmortem Aging Effects on Beef Tenderness

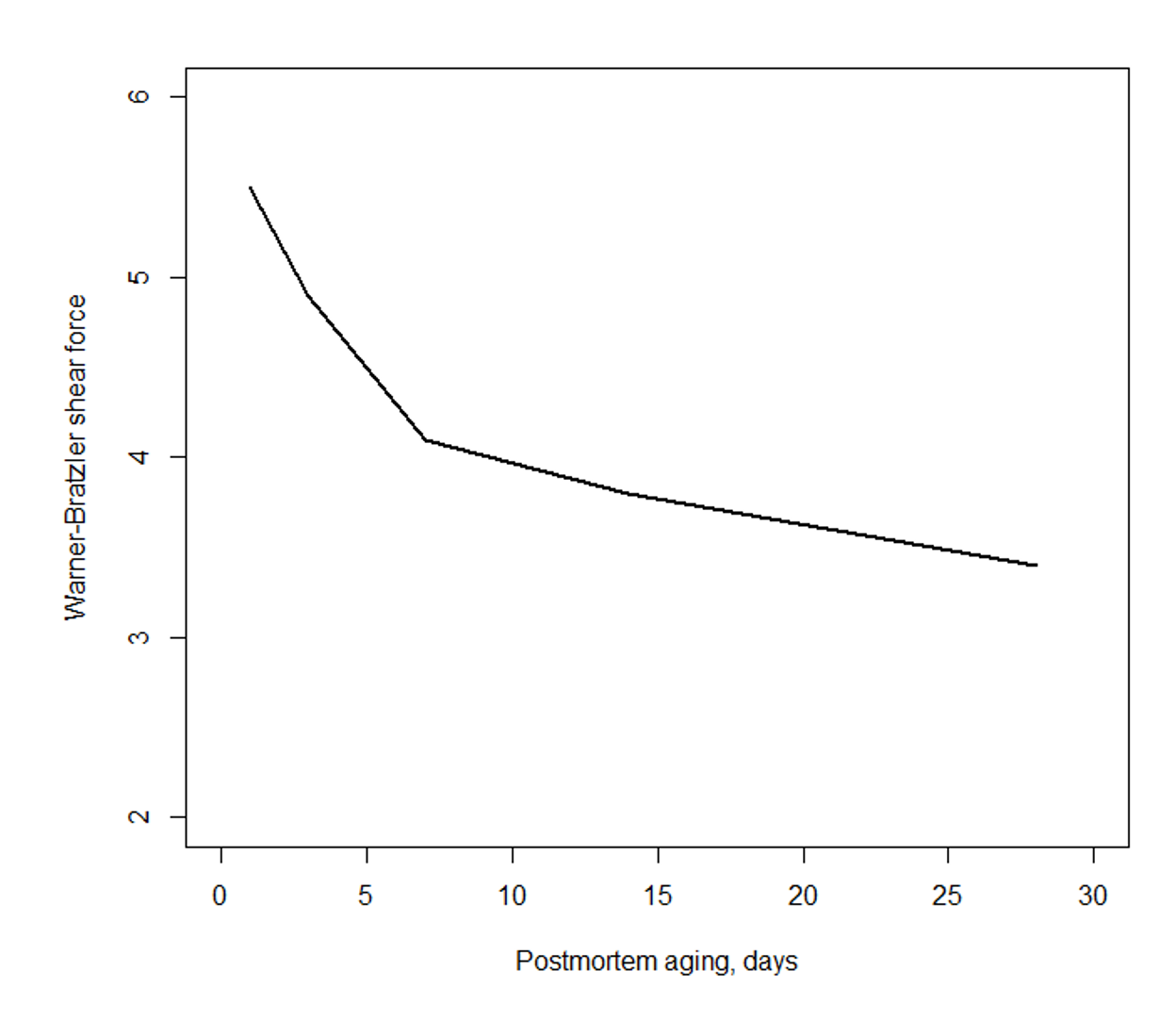

Figure 3 illustrates the beneficial effects of aging on tenderness as measured in a laboratory as Warner-Bratzler shear force. This naturally tenderizing process ceases once meat is frozen. When possible, postmortem aging should be at least seven to 15 days to reach threshold shear force values for consumer acceptable tenderness of 8.3 pounds to 10 pounds (3.8 kg to 4.6 kg). Aging beyond this timeframe is often restricted due to the processor's cooler space, but could result in further improvements in tenderness.

Figure 3. Effect of aging on forage-finished beef tenderness as determined by Warner-Brazler shear force (adapted from Schmidt et al., 2013).

Was this information helpful?

YESNO

carringtonbroated98.blogspot.com

Source: https://extension.okstate.edu/fact-sheets/finishing-beef-cattle-on-the-farm.html